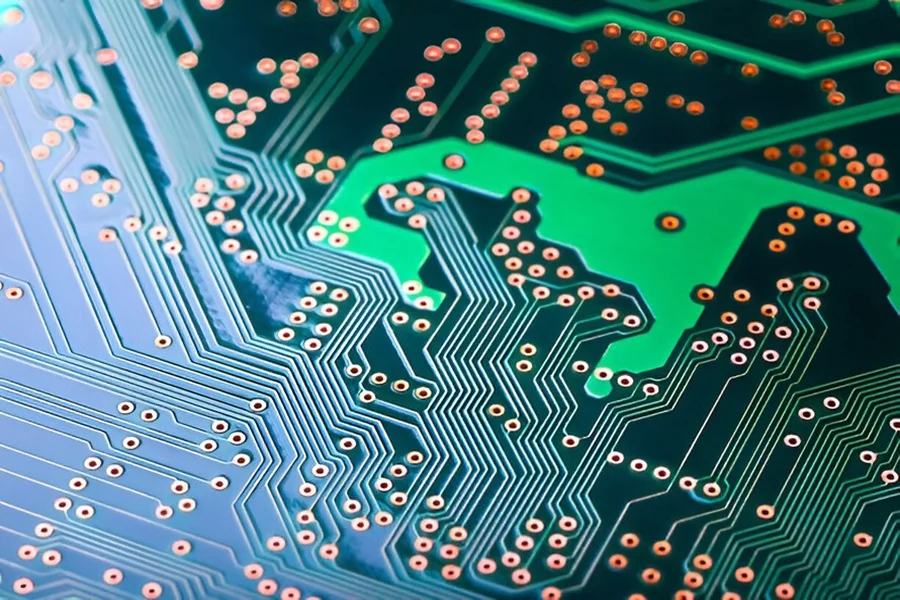

In today’s fast-paced industrial landscape, technology drives productivity, efficiency, and innovation. At the heart of many of these advancements lies a critical component—the Industrial PCB. Short for Printed Circuit Board, an Industrial PCB is designed to operate in demanding environments where reliability, durability, and performance are paramount. From factory automation to robotics, these boards are the backbone of electronic control systems across various industrial sectors.

What Is an Industrial PCB?

An Industrial PCB is a specially engineered circuit board used in equipment that operates in manufacturing, heavy machinery, automation, and processing environments. These boards are built to withstand harsh conditions such as extreme temperatures, vibrations, dust, moisture, and electrical noise. Unlike consumer-grade electronics, Industrial PCBs must meet stricter standards for long-term stability, thermal management, and ruggedness.

Applications of Industrial PCBs

Industrial PCBs are used across a wide range of industries. In automation systems, they control sensors, actuators, and robotic arms that maintain assembly lines and ensure smooth production flow. In power plants and energy systems, PCBs monitor performance and facilitate communication between various subsystems. They’re also integral to instrumentation, motor controllers, measurement devices, and data acquisition systems.

The versatility of Industrial PCBs makes them suitable for use in:

- Manufacturing equipment

- Oil and gas processing units

- Industrial robotics

- Power converters and inverters

- Environmental monitoring systems

- Mining and heavy equipment

- Industrial Internet of Things (IIoT) devices

Design Considerations for Industrial PCBs

Designing a PCB for industrial use involves a combination of high-performance engineering and material selection. Signal integrity, electromagnetic compatibility (EMC), and power distribution are critical factors in ensuring the board can function reliably in electrically noisy or high-load environments. Materials must be flame-retardant, offer thermal stability, and support multilayer designs when complex circuits are required.

Industrial PCBs often include thicker copper layers to handle high currents and advanced heat dissipation systems such as heat sinks or thermal vias. Additionally, protective coatings like conformal coatings and encapsulation help protect the PCB from moisture, dust, and chemical exposure.

The Manufacturing Process

The production of Industrial PCBs involves several stages, from prototype development to mass manufacturing. At each stage, precision and quality assurance are key. High-speed drilling, fine-line imaging, multilayer lamination, and surface treatments like ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) ensure long-term performance and reliability.

At Viasion Technology Co. Ltd, each stage of PCB manufacturing is closely monitored using advanced testing protocols like AOI (Automated Optical Inspection), electrical testing, impedance control, and thermal cycling. These steps are crucial in detecting any defects before the final product is shipped to customers.

Key Challenges in Industrial PCB Production

One of the primary challenges in manufacturing Industrial PCBs is maintaining reliability under extreme operating conditions. High humidity, corrosive chemicals, fluctuating voltages, and physical shocks can all affect board performance. As a result, designers and engineers must incorporate redundancies and fail-safe mechanisms.

Another major concern is compliance with industry standards such as IPC-A-610, ISO 9001, and RoHS. These certifications ensure that the boards meet both safety and environmental guidelines. A reliable supplier must be able to comply with global regulatory standards to serve clients worldwide.

Customization and Scalability

Each industrial application has unique requirements. Whether it’s the form factor, voltage tolerance, number of layers, or component footprint, Industrial PCBs often need to be custom designed. This level of customization requires in-depth consultation and prototyping, especially when dealing with legacy equipment or upgrading existing systems.

Viasion Technology Co. Ltd excels in this area by offering fully customized solutions based on a client’s functional and mechanical requirements. From small-batch prototyping to large-volume production, their manufacturing systems are designed for scalability and flexibility. This makes them an ideal partner for businesses looking to future-proof their industrial systems.

Future Trends in Industrial PCBs

As Industry 4.0 and smart manufacturing continue to evolve, the demand for intelligent and connected PCBs is on the rise. Technologies like embedded sensors, edge computing, and machine learning are pushing the boundaries of what Industrial PCBs can do. Integration with IIoT systems means these boards are no longer just passive components but active participants in data gathering and real-time decision-making.

In addition, innovations in materials—such as high-temperature laminates and flexible hybrid electronics—are allowing PCBs to perform better in tighter, more dynamic spaces. The shift toward environmentally friendly and lead-free manufacturing is also shaping how PCBs are designed and produced.

Conclusion

In the modern industrial environment, the role of PCBs has become more critical than ever. Industrial PCBs enable automation, precision control, safety monitoring, and data management across a wide range of industries. The ability to function reliably under harsh conditions while maintaining signal integrity and durability makes them an indispensable part of industrial electronics.

With decades of experience, advanced facilities, and a commitment to quality, Viasion Technology Co. Ltd is a trusted name in the field of Industrial PCB manufacturing. Their dedication to delivering customized, high-performance, and standards-compliant solutions positions them as a preferred partner for industries looking to enhance operational efficiency through robust electronics.